Taste the Future

There is something prehistoric about human beings eating meat. Despite our cultural advances, when it comes right down to it, a steak is still the result of a slaughtered cow and some fire. The problems with the historical meat model are many; Diseases like mad cow, famine in places that lack substantial farming, the health factor of fatty meats, not to mention hordes of dead animals. A small percentage of the population work themselves out of the equation by foregoing meat entirely. However, most of us still like a good steak or a juicy hamburger now and again, not to mention a chicken wing or a slice of bacon. So why is the meat business still struggling with the industrial revolution while other major commodities are already moving to hyper industrialization or new models entirely?

There is something prehistoric about human beings eating meat. Despite our cultural advances, when it comes right down to it, a steak is still the result of a slaughtered cow and some fire. The problems with the historical meat model are many; Diseases like mad cow, famine in places that lack substantial farming, the health factor of fatty meats, not to mention hordes of dead animals. A small percentage of the population work themselves out of the equation by foregoing meat entirely. However, most of us still like a good steak or a juicy hamburger now and again, not to mention a chicken wing or a slice of bacon. So why is the meat business still struggling with the industrial revolution while other major commodities are already moving to hyper industrialization or new models entirely?Part of the problem is the "ethics" of meat. The other hurdle, like with the farming of food crops, is that some people simply have an aversion to science encroaching on their dinner table. But despite a few stumbling blocks, there are some people working to bring meat out of the dark ages. The first tentative steps were taken over a decade ago in Europe, when Marlow developed a product called Quorn. Quorn is relatively new in the states, but Europe has been enjoying it for years. It's remarkably like chicken, but contains no real meat at all. Quorn is actually mycoprotein, derived from a previously obscure fungus and fermented in massive bioreactors for your dining pleasure. It may not sound appetizing, but I am told that Quorn is far more like real meat than any other substitutes, and loads more "authentic" than products made from soy.

I will be picking some up after posting this article and giving Quorn the Pepsi challenge.

Wired covered Quorns emergence into American kitchens back in 2002, and results were mostly positive. There was a dust up over Quorns original claims that it was made from mushrooms. But a quick look at their website tells you that the makers of Quorn are now proud of it's high tech mycoprotein roots. But although Quorn solves some of the problems with the meat model, it's not really playing by the rules. Deliciousness aside, although similar to meat, products like Quorn and the new Valess are still just synthetic meat substitutes. So where are the T-bones of he future?

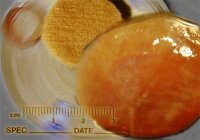

They are currently taking shape inside Dutch bioreactors and labs in Maryland and Hawai'i, if New Harvest has anything to say about it. The Dutch government recently allocated $2.5 million for research into growing real meat from cell cultures on an industrial scale. Lead by Professor Henk Haagsman of Utrecht University, the dutch team is attempting to grow minced pork meat from pig stem cells in mass quantities. They predict successful results by 2009. In Hawai'i, Tissue Genesis' vice president of engineering Paul Kosnick, believes that with the proper funding a vat grown meat product would be possible within five years.

Jason Mathery, director of New Harvest and a doctoral student at the University of Maryland, envisions scores of industrial bioreactors. Some for producing the originating stem cells, some for producing the medium that the meat will have to be grown in, and some actually growing the meat in thin sheets to be layered into finished products. This would eliminate all of the overhead of running an old school animal farm. And in fact could take place inside any suitable structure from first cells to final product. No longer would the third world have to worry about good grazing lands or diseased animals. And test tube meat is an order of magnitude more efficient than the animal variety. With the animal, you have a whole life cycle to worry about, and all the energy that goes into keeping a fully living body in healthy shape. But in the lab, you only need to see to the needs of the actual tissues being grown for consumption. Mathery says;

"To produce the meat we eat now, 75 (percent) to 95 percent of what we feed an animal is lost because of metabolism and inedible structures like skeleton or neurological tissue. With cultured meat, there's no body to support; you're only building the meat that eventually gets eaten."

This may sound ghastly to some of you, but Jason has a very interesting way to look at it.

"We already eat meat that's processed in vats - chicken nuggets. But if we grow a better steak using cell cultures, we could give it the fat content of salmon, eliminate pathogens like salmonella, and save tens of millions of animals a year. Sure cultured meat isn't natural But neither are the processes for creating cheese or wine - not to mention stuffing 10,000 into a metal shed and pumping them with drugs."

One of the big positives in cultivated meat is that we could decide on its make up as it was being made. Beef, pork, chicken or what have you could be a hundred times more healthy than its "natural" counterpart. It could also be grown to specific compositions, textures, and tastes. I could foresee a time when meat cultivation centers become as famous for particular cultures of meat, just like certain vineyards are now renowned for their unique wines. And why stop there. What's to say that you couldn't put a microwave sized bioreactor in every kitchen, where tomorrow's New York Strip could be grown to order today.

It would be healthier, more plentiful, made to suit individual tastes, dead animal free, and available anywhere you had some floor space and some sunlight. When New Havest starts passing out the cultivated vat grown cheese burgers at the 2009 BBQ, I'll be a the head of the line. Until then, I suppose we'll have to get our delicious beef the old fashioned way. Bon appetit! [via Wired]

"The flesh. It should make the computer crazy, like those old ladies pinching babies. But it doesn't, not yet. I haven't taught it to be made crazy by the flesh, the poultry, the steak. So I'm going to start teaching it now!" - Seth Brundle

2 Comments:

So how well would this process of "growing" meat work in space?

- rook

Similar to here; growing tissues or cultures in a bioreactor is largely unaffected by gravity. The air pumped into it would have to be at a slightly lower pressure and it would have to be spun so wastes gases could be removed. Bioreactors are more affected by the slight current generated by its' impellers.

Post a Comment

<< Home